Sealcoating Equipment Cost Calculator and a Guide on Sealcoating Cost Per Square Foot

How much does sealcoating an asphalt parking lot or driveway cost? What sealcoating equipment do you need? What factors affect the total cost of asphalt sealcoating? And why is regular sealcoating so important for your property?

If you’re a property manager, contractor, or homeowner looking to budget for your next sealcoating project, then this page is for you.

Protecting your asphalt investments doesn’t need to be complicated. From the cost of equipment, supplies, labor, and factors that affect sealcoating cost, we’re taking out all the guesswork for you. We’ll guide you through everything you need to know about…

- Sealcoating cost

- Why sealcoating is crucial for maintaining your property

- The profitability of sealcoating

- Average sealcoating cost per square foot

- Different sealcoating equipment and their costs

- What factors affect total sealcoating cost

- When to hire professional sealcoaters versus doing everything yourself

And if you’re worried about how much raw materials will cost you, you don’t need to. You’ll get a sealcoating calculator that’ll give you the exact costs based on the size of the area you’re planning to cover.

So, let’s get to it.

Why is sealcoating important?

Can you really save 10X money when you sealcoat your property? More homeowners and property managers in America are sealcoating their pavement. That’s because sealcoating is an absolute must, and it goes beyond adding curb appeal to your property.

It’s a protective coat that can damage-proof your asphalt, so it can last for up to 36 years.

Like how we wear sunscreen to prevent our skin from getting dark spots, applying a sealant to your pavement protects it from damage caused by UV rays, gasoline, weathering, and other contaminants. It keeps water out of those porous areas so they don’t crack or deteriorate quickly.

Without it, your asphalt pavement can develop cracks, chips, and potholes. And if further left to the elements, this deterioration can lead to more repairs later on.

If potholes and cracks reach a state that not even seal coating can repair, this could require a complete repaving – which is by no means cheap. A total repaving costs at least $10,000 on average.

Compared to an average cost of $0.15 and $0.25 per square foot, sealcoating is a more inexpensive way to extend the life of your pavement. Seal it with a quality sealer, and give yourself peace of mind knowing that you’ve done all you can to extend the life of your pavement. Done regularly, sealcoating can maintain the appearance and durability of any asphalt surface for more than 30 years if there are no structural issues.

The cost of sealcoating

If you’re going to get professional sealcoaters to do the job, the typical sealcoating cost would range between $0.08 to $0.30 a square foot.

This means that, on average, you can expect to pay between $48 to $180 to sealcoat a 600 square foot parking space.

If you prefer to DIY, the cost could range between $0.15 and $0.25 per square foot. However, you also have to factor in the time and effort you’ll need to spend to do all the sealcoating yourself.

For the average homeowner, seal coating is an easy task. You can simply buy a sealant and squeegee to coat your driveway yourself. But if you have a large area, such as a commercial parking lot, DIYing is not the most practical or cost-effective use of your time.

How much would it cost to seal coat different parts of your property?

Depending on the type of property you’re planning to seal coat, they’ll vary in size. Often, the larger the surface area, the higher the cost of sealant and labor.

In the table below, discover how much you can expect to spend depending on the type of area you’re sealcoating.

| Type |

Average size |

Estimated cost per square foot |

Estimated total cost per type |

| Residential Driveway |

640 square feet |

$0.15 – $0.25 |

$96 – $160 |

| Commercial Parking Lot |

246 square feet per car |

$0.15 – $0.25 |

$36.9 – $61.5 |

| Patios |

288 square feet |

$0.15 – $0.25 |

$43.2 – $72 |

| Walkways |

200 square feet |

$0.15 – $0.25 |

$30 – $50 |

| Basketball & Sport Courts |

4,700 square feet |

$0.15 – $0.25 |

$705 – $1175 |

What equipment do you need for asphalt sealcoating?

Do you want to DIY or offer sealcoating as a service? Below you’ll find a more detailed breakdown of what equipment and materials you will need for sealcoating and how much they’ll cost you on average.

Getting a quick look can help you eyeball how much you need to spend and how much profit you can realistically make.

SUPPLIES NEEDED FOR CLEANING BEFORE SEALCOATING

Cleaning the surface of debris is imperative before sealcoating your blacktop. If you don’t, the asphalt sealer won’t stick and protect it from wear and tear. After all your hard work, the sealer will start to flake or peel off over time. The table below helps prevent this from happening.

Discover the different cleaning materials used to prepare your surface for sealcoating.

| Material |

Definition |

Cost |

| Gas Blower |

Cleans all dirt, debris, and sand from the surface. |

$1000 – $1900 |

| Degreaser Cleaner for Asphalt |

Effective in removing grease, oil, gas drips, and leaks on your asphalt surface. This eco-friendly degreaser penetrates the asphalt and protects the surface from further damage caused by these drips. |

$90 |

| Scrub Brush |

Clears the surface of flaking paint to ensure the asphalt sealing adheres to the surface. |

$40.00 |

| Water and Hose |

A water hose helps clear the surface of debris before sealcoating. |

$30 |

SUPPLIES NEEDED FOR SEALCOATING

When the surface is clear of debris, you’re ready to apply your sealant. Make sealcoating effective and convenient through the materials listed below.

| Material |

Definition |

Cost |

| Asphalt Sealer |

Filling in small fissures, an asphalt sealer prevents water and ice from causing damage to your asphalt. It protects it from the elements and usually has a black matte finish that adds curb appeal. |

$464 – $533 for a 55 gallon drum |

| Crack Pour Pot |

Most people are tempted to apply a sealant to cover cracks. However, cracks will soon turn into potholes forcing you to shed money for repairs. A crack pour pot helps fill cracks at walking speed and helps pour crack sealer even in hard-to-get areas, helping you save time and reduce waste. |

$180 |

| Liquid Crackfiller |

Easily seal small cracks with a liquid crack sealer and your pour pot to prevent water from penetrating the gaps in your asphalt. |

$120 for four gallons |

| Sealcoating Machine: Asphalt Sprayer |

A sealcoating machine helps apply the sealer in the fastest way. |

$899- $17,500 depending on size and complexity |

Sealcoating Broom or squeegee

[For small driveways] |

For small areas like a residential driveway, you can use a squeegee or a broom to apply the sealant. Sometimes, it’s specified on the sealant’s label which tool is best to use. |

$40 |

| Pylons, Saw Horses, Caution Tape |

Prioritize work safety by blocking off the area with pylons and caution tapes. These tools help keep traffic out while you work. |

Pylons = $30

Saw Horse = $40

Caution Tape = $30 |

| Cardboard and Tape |

Block off and protect curbs, lawns, sidewalks, and anything else you don’t want to be stained by the sealer. |

Cardboard = $17

Tape = $10 |

| Mixing paddle |

Use a mixing paddle to mix the sealer. |

$20 |

Alternatively, you can get a DIY Patch & Seal Driveway Package.

Sealcoating Equipment Cost Calculator

What sealcoating supplies will I need? How much do I have to budget for sealcoating my driveway? How many buckets or drums will I need for a commercial parking lot?

These are just some of the questions that can make sealcoating quite a challenge. Thankfully, we’ve made things simpler for you.

To get the right amount of asphalt sealcoat that you’ll need for your project, simply follow the instructions below:

- Select whether you’ll be using a squeegee, a roller, brush, or sprayer to apply your sealcoat

- Enter the total number of square feet you will be sealing

- Click Calculate.

Use the Sealcoat Calculator

Note:

If you like the results, you have the option to click “Add To Cart”. This will take you to the Asphalt Kingdom checkout so you can get your sealcoating equipment delivered right to your doorstep.

What factors affect total sealcoating cost?

There are a few factors that can affect how much a sealcoating project will cost, and this includes:

1. Labor costs in your area

Some regions in the US prove to be more convenient than others when it comes to weather conditions and material cost. Some regions have harsh weather that can make labor costs higher compared with other areas, so there’s no single price for a professional sealcoating job.

2. The type of asphalt sealer you’ll use

Below, you’ll learn about the different types of sealers. Weigh the differences in prices and the pros and cons of each, and decide which sealant is the best fit for your sealcoating project.

| Type |

Pros & Cons |

Estimated Cost |

Drying time |

| Coal Tar Emulsion |

Pros:

With coal tar sealer, you’ll get an extra layer of protection against gasoline spills, motor oil pollutants, waters, and UV light from the sun. These factors can cause your asphalt to crack prematurely or even crumble away completely if they’re not protected by a high-quality sealer like this one.

Cons:

Coal tar poses environmental and health concerns. That’s why it’s banned in some municipalities. It doesn’t have the dark black color of fresh asphalt because it’s naturally dark gray.

|

Around $465 per 55-gallon drum for 5,500 square feet coverage, or 100 square feet per gallon. |

Between 3 to 4 hours. |

| Asphalt Emulsion |

Pros:

Asphalt emulsion is water-resistant. Unlike coal tar, asphalt emulsion results in a more satisfying dark black color.

Cons:

Asphalt emulsion sealant is not UV resistant. It doesn’t provide much protection. It only lasts for a single season and fades relatively quickly.

|

Around $533 per 55-gallon drum for 5,500 square feet coverage, or 100 square feet per gallon. |

Approximately 8 hours. |

| Acrylic |

Pros:

Acrylic is popular for tennis courts and shopping mall parking lots because it’s available in different colors. It’s environmentally friendly, durable, and water-resistant. Depending on the traffic, it can last for seven years before needing to be reapplied.

Cons:

It’s the most expensive choice.

|

Upwards of $900 for a 55-gallon drum. |

Approximately between 4 to 12 hours. |

| Fast Dry |

Pros:

It cures in less than an hour so it’s often used by road crews and owners of large parking lots.

Cons:

It’s difficult to buy in small quantities resulting in a higher price tag.

|

Fast dry additives start at $120 per 5-gallon pail. |

Can dry in less than an hour. |

| Oil-Based |

Pros:

An Oil-based sealant does not have many advantages.

Cons:

It often takes seven days to cure, the longest of all common sealer options. Hence, it’s a bad choice for those who need to paint lines. It also has a distinct odor that lasts for days. Unlike coal tar sealants, it doesn’t protect against UV rays or petroleum products.

|

Around $825 to $1,100 for 5,500 square feet of coverage. |

Up to several days. |

3. How many coats of sealer do you need to apply?

What type of project are you working on? The more traffic, the more coats!

If you’re looking for a coat or two to keep your asphalt safe from weathering, it all depends on how much traffic you expect.

For low-traffic jobs like driveways and backyards, one layer should suffice. If you’ve got a high-traffic area like a parking lot or construction site that needs protection against everything from rain to snow and ice, then two to three layers will do the trick!

- One Coat

- Best used for areas with low-traffic and areas that do not endure vehicle weight.

- The labor cost is approximately $0.08 to $0.30 per square foot

- Two Coats

- Best used for areas with a lot of traffic such as a commercial parking lot.

- The labor cost is approximately $0.12 – $0.45 per square foot.

- Three Coats

- Best used for areas that endure heavy vehicle traffic including trucks and buses.

- The labor cost is approximately $0.16 – $0.9 per square foot.

Remember to wait at least eight hours before applying another coat. Giving it enough drying time helps the water to evaporate, resulting in a more quality finish for your sealcoat. You should also read our comprehensive Guide To Sealcoating Asphalt On Your Property.

| Type |

Description |

How Many Layers of Sealcoat Needed |

| Residential Driveway |

Endures less traffic. Does not handle heavy vehicles. |

1 coat |

| Commercial Parking Lot |

Has more traffic than a residential driveway. |

2 – 3 coats |

| Patios |

Does not endure vehicular traffic. |

1 coat |

| Walkways |

Only endure bicycle and pedestrian traffic. |

1 coat |

| Basketball & Sport Courts |

Does not endure vehicular traffic. |

1 coat |

4. Sealing Preparations

Take note that sealing preparations are often more tedious than the coating itself. If you include the drying time, sealing preparation such as cleaning and doing repairs can take a full day. Meanwhile, applying the sealer itself can take only a few hours per coat.

Cleaning

It’s important to clean any oil, dirt, or debris in order for the sealant to bond. If you fail to clean the surface before sealcoating, it can result in flakes and shedding of the sealcoat.

Using a gas blower, degreaser, scrub brush, and water hose, you can clean the surface on your own.

However, if it’s too oily and filled with too much debris, it should be handled by professionals. They’ll scrub and/or power wash it until it’s clean enough to take the sealant.

On average, power washing costs $280.

Asphalt Repairs

Sealcoating is meant to protect the surface of your asphalt. However, it’s useless when fixing chips or cracks. When you see these damages, it’s too late to apply a sealant. If you just cover them up, they’ll soon turn into potholes that’ll result in more expensive repairs in the future.

Repair these damages first before sealcoating. You can expect to pay around $1 to $4 per square foot to smooth out or fill in any cracks, chips, or fissures. The wider the cracks you have on your surface, the more you can expect to pay for crack filling and patching.

5. Surface size

The surface size depends on the type of project you’re working on. For example, a small residential driveway would be smaller in size compared to a commercial parking lot. Hence, you’ll need less sealant and labor. This means a residential driveway is cheaper to sealcoat in comparison.

However, sometimes the smaller the area, the higher the labor cost per square foot. This is because you’ll need to cover the contractor’s transportation cost and the preparation time.

6. Mobilization Costs

They say time is money and that seems to be the case for contractors. If it takes longer to finish a project because of shorter days or multiple coats required then there will be higher mobilization costs. Another factor affecting this fee is the distance between the project site and the contractor’s base.

7. The Complexity of the Project

Using a machine like an asphalt sprayer makes sealcoating faster and easier to do. You can also cover more ground in less time.

However, areas that are close to buildings, landscaping, and other sensitive areas may require manual application. The added labor and time consumed increases the cost of the project.

8. Cost of Materials

The ingredients in the asphalt sealer, such as oil, can change in price depending on the time of the year. If the sealer is made during a time when these ingredients are expensive, it can increase in price.

Warning for New Asphalt Surfaces

Before applying sealant, the asphalt surface should be at least 6 months to 1 year old. You see, as the oils evaporate, the fresh asphalt remains soft and flexible.

If you want a stronger pavement, it’s important to let those chemicals cure and harden before covering it with a sealcoat.

The Profitability of Sealcoating

For homeowners and property managers, sealcoating can save you 10X more money than doing asphalt repairs and repavement. It can also add curb appeal that attracts more tenants or potential buyers to your property.

For sealcoating contractors, your profit is entirely up to you. You could either sealcoat on the weekends and earn a couple of hundred dollars, or you could make thousands every day.

Asphalt sealcoaters can make $125 per hour on average. That means, 20 hours of work is all you need to make back your investment. However, keep an eye on some of the factors below that could affect your profitability.

Factors That Could Affect Your Profitability:

- Number of leads: The number of leads you attract is critical to growing your sealcoating business. Grow and nurture your leads into customers by optimizing your website, networking, and staying active on social media.

- Weather Conditions and Season: You can expect summer to be the peak season for sealcoating projects. Meanwhile, rainy days can certainly affect how much you earn for the week.

- Size of the Project: The larger the surface you need to sealcoat, the more you can charge for it. You must also consider the number of coats you need to do. Usually, an additional coat is an added 50% on your total charge. For example, if you charge $0.15 per square foot, then an additional coat would mean charging a total of $0.23.

Read our Asphalt Sealing Business Strategy guide.

When is it Too Late to Sealcoat Your Driveway?

When’s the best time of year to sealcoat my driveway? It may be too late to sealcoat when it’s been years since the last time you’ve paved your driveway and you notice that the asphalt has faded significantly.

Fading usually means the asphalt is becoming brittle as the bitumen from the asphalt mix evaporates, which is a sign that it’s time for you to sealcoat your driveway.

Here are more factors you’ll need to reconsider before sealcoating your pavement.

Weather

To cure the sealcoat, you need air temperature above 50 degrees Fahrenheit. That’s why summer is usually the peak season for sealcoating. When it’s winter, it’s usually too late. If you try to sealcoat your pavement in poor weather conditions, you can expect your $500 sealant to freeze and peel off, or get washed away by rain.

Are you planning to seal off your commercial parking lot? If you can’t afford to have the lot off-limits for too long, you must have it sealed in June, July or August. The warm weather will allow the sealant to dry faster.

Repairs Needed

Often, we sealcoat our property to protect the pavement from weathering. However, when you can already observe wide cracks and potholes, it’s too late.

First, you must fill and patch these holes, or repave them. If you attempt to cover the cracks with a sealcoat, they will continue to get bigger. The damages will soon demand larger repair fees, costing around $1-$4 per square foot for asphalt repaving. Fill the cracks and fix the damages soon before adding a sealcoat.

When to Hire Professional Sealcoaters vs Doing Everything Yourself

DIY Sealcoating

Pros

Saving money on labor fees is the biggest benefit of doing sealcoating by yourself. Because you’re completely in charge of the task, you can ensure the work meets your standards, and that you use quality materials. It can also be a fun bonding opportunity with your family.

Cons

If you’ve never done sealcoating before, you could buy poor-quality tools and supplies. The cost savings can be minimal and not worth the hassle of trial and error.

If you don’t like ruining your clothes in the process and suffering from skin irritation, then DIYing is not for you.

The worst risk about doing it yourself is needing to spend and redo the project again when you’ve made a mistake during the sealing preparation.

In summary, DIYing is best for people who have experience sealcoating asphalt. If you’re considering it, assess if the cost savings is worth the risk of re-doing the project as a result of trial and error.

Hiring a Professional Sealcoater

Pros

Hiring a professional removes the hassle and guesswork that goes with sealcoating your asphalt for the first time. A professional can quickly repair wide cracks and damages that can be a challenge for DIYers.

Cleaning, repairing, and sealcoating your asphalt is more likely to be higher in quality compared to DIY. It’s often the best option when you can’t afford any trial and error and need a quick turnaround.

Cons

Picking the right sealcoating contractor can be a hassle. The cost estimates can vary, and with so few contractors per area, you may need to wait some time before getting on their schedules.

Hiring a professional is best for people who need assurance of quality work and quick turnaround time.

Try to look for a contractor that’s near you to save on mobility costs. Most importantly, look for their customer reviews so you can assess if they’re the best fit for your project.

Frequently Asked Questions

- How often should you seal asphalt?

On average, an unsealed surface can last approximately 12 years. But with factors like extreme climates, traffic, and enduring heavy vehicles, an unsealed pavement most of the time lasts for only three years. Studies show that sealcoating extends the life of a pavement by 3 times.

The bitumen is the binder for asphalt, adhering the asphalt aggregates together and making it resistant to damage from water and oil spills. Once you’ve noticed that your asphalt’s color has started to fade, it means the bitumen has evaporated and the asphalt has turned brittle. It’s a clear sign that it’s time for you to apply sealant on it.

In areas with extreme heat or cold, you should seal your driveway every other year to protect it from the UV rays of the sun, or the extreme winter weather. In less extreme areas, you can seal the surface every three years.

- What are the complications of unsealed pavement?

Failing to sealcoat asphalt often results in potholes and uneven cracks. People can trip and fall, which could result in legal cases. It can also result in damaged vehicles and so on.

Pedestrians, cyclists, and animals could trip or fall and result in legal cases. It can also be a hazard to drivers.

Because they are forced to slow down to avoid the hazard on the road, it creates traffic jams that sometimes result in frustrations and accidents. The potholes and cracks resulting from the lack of sealcoat often damage vehicles, affecting the tires, wheel alignment, and suspension. This results in money spent on vehicular repairs.

- What is an asphalt crack filler and which product is best?

It’s important to seal the cracks on your pavement no matter how small to prevent them from turning into potholes. That’s what an asphalt crack filler is for.

You can buy the best quality asphalt crack filler here.

- What are the benefits of sealcoated asphalt?

A sealcoated asphalt surface adds curb appeal to your property. This attracts tenants and customers if you own a rental property or a business. It also helps you save money from long-term repair costs.

You see, sealcoating can preserve the life of your pavement by three times. That means you can get 36 years out of asphalt pavement assets.

Lastly, because it protects your pavement from fuel spillages and cracking under pressure, sealcoating promotes safety for pedestrians, cyclists, vehicle drivers, and passengers.

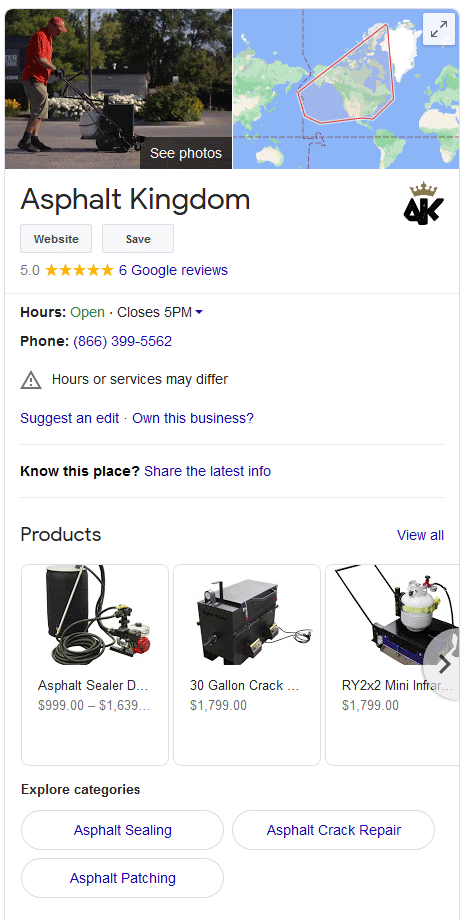

It’s important to get verified as soon as possible, so don’t put that step off for another day. Once you are verified, you can post pictures, videos, services and more.

It’s important to get verified as soon as possible, so don’t put that step off for another day. Once you are verified, you can post pictures, videos, services and more. To make these edits, log into your Google My Business dashboard, click on Info, and then click the pencil next to the property you’d like to update. There are nearly 4,000 of them so it takes a little filtering, but you want to be very accurate so you maximize the amount of traffic your listing receives. Some sample categories:

To make these edits, log into your Google My Business dashboard, click on Info, and then click the pencil next to the property you’d like to update. There are nearly 4,000 of them so it takes a little filtering, but you want to be very accurate so you maximize the amount of traffic your listing receives. Some sample categories: