Select grades of clean angular, quartz sand or aggregate are commonly added to sealcoatings. Boiler slag or coal slag, which is an amorphous mixture of Iron, Aluminum and calcium silicates, is available under the brand name Black Beauty, also commonly used with seal coatings. In the following paragraphs, the descriptions mentioning sand, largely apply to Black Beauty as well. Both materials supply the following benefits:

• Improved traction and skid resistance.

• Improved longevity.

• Hiding minor surface defects and filling hairline cracks,

• Uniform textured appearance, reduction in sun glare and streak-free appearance.

1. For normal textured pavements: 2 to 2.5 lbs. per gallon of undiluted sealer.

2. For rougher pavements, sand loading of 4 to 4.5 lbs. per gallon of undiluted sealer is used to accomplish proper texturing and filling of the surface profile.

Sand shall be used in recommended quantities, per sealer manufacture’s recommendations.

• Too little sand or no sand: You will not have above-mentioned benefits.

• Too much sand: The sealer may become brittle, lose flexibility and its resistance to chemicals, fuel, salts, etc.

Sand has a certain degree of porosity, therefore, its own need to absorb liquids. When added to the sealer in a mix design, it absorbs the binder (refined tar or asphalt) and water from the sealer. The amount of sand in the sealer must be limited to the extent where it does not absorb excessive amounts of the binder from the sealer, otherwise binder will not be available to bond to the pavement and form a continuous film. The limit is reached at about 5 lbs. of sand per gallon of sealer. At this level, binder and filler in the sealer system are still in balance to expect optimum performance. Sand loading exceeding 5 lbs. will rob the binder from the sealer, thus rendering the sealer film, porous, brittle, poor in adhesion and resistance to chemicals, salts, fuel, etc.

Sand Must Be:

• Clean, water-washed, pure silica type, with irregular particle shape

• Free of contaminants, metals, clay, trash and organic matter

• Of fineness 50-75 MESH AFS (American Foundrymen Specification)

• Angular

Sand Gradation – Why is it so important?

In selecting sand, it is imperative that the average particle size be very close to the cured film thickness of the sealer. The sand particles should be at least 2/3 imbedded in the cured sealer film. For example, a sealer applied in two coats (at 25% dilution) will dry to approximately 11-13 mils. Therefore, the AFS of the sand shall be around 50-70.

One of the most common ways of measuring and specifying particle size of sand is by the use of sieves, often called meshes or screens.

How do they work? Particle sizes are separated industrially or in the laboratory by passing material over sieves that have openings of certain specified sizes. These sieves can range from extremely coarse devices that look like sewer grates for large size separations [range of inches] to sieves that look very much like window screens for middle separations [millimeter], to very fine woven screens for fine separations [~50 micrometers]. Separation can be either dry or wet. Wet screening is more efficient, but drying of the product adds cost.

What do the numbers mean?

Each sieve has a number, such as 20 mesh, 50 mesh, 200 mesh, 325 mesh. This number relates to the number of openings in the screen per inch.

Lower the sieve number, larger is the screen opening and coarser the particles passing through it, e.g. a 20 mesh sieve has a screen opening of 33.5 mils, whereas a 50 mesh sieve has screen opening of 11.7 mils. Modern practice is to refer to the screen by the size of the opening in microns, but for our purpose mil unit suits better because we denote the cured film thickness in mils.

Some Units:

1 millimeter (mm) = 1000 microns

1 millimeter = 39.37 mils.

1 mil = 1/1000 of an inch

1 micron = 0.03937 mils.

Sand/ Aggregate Selection

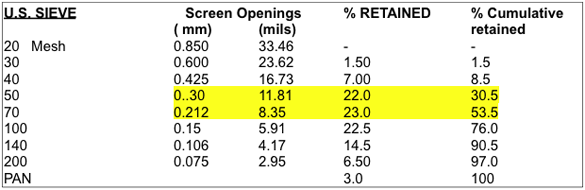

Sand is supplied in different grades, classified according to their average particle size and denoted as AFS (American Foundrymen Specifications) numbers. For example, AFS 60 grade has majority of the particles passing through a 60-mesh screen. Sieve analysis of one of the recommended grades, No 1, Dry Sand from Central Silica follows:

Sand/Aggregate shall not have

1. Too many fines i.e. finer than 200 mesh.

Sand particles absorb water and binder from the sealer and the degree of absorbency increases with the surface area. The surface area increases with the number of particles, for the same weight of sand. For example, one pound of 200-mesh sand has 4 times the surface area of sand at 50 mesh. Sand with too many fines will soak up excessive binder amounts from the sealer, thus resulting into poor performance of the sealer.

2. Too many coarse particles, coarser than 30 mesh.

Too many coarse particles will not have enough fines to effectively interlock, knit and reinforce the cured sealer film. Additionally they will not be properly anchored in the cured sealer film and are likely to be dislodged from the cured film under traffic. The loose sand thus dislodged, acts as a sand paper on the cured sealer film and may cause premature failure.

Ideally, the major proportion of sand particles in a particular grade should fall within 40 to 100 mesh to properly interlock without placing excessive demands on the binder (for surface absorption and saturation of the sand particles). Sand with medium fineness between 50 to 70 AFS rating produces the best results.

Sieve analysis should be thoroughly checked prior to selection of a grade.

Do not use these types of Sand or Aggregate

1. Recycled sand from steel sand blasting. It has lots of iron and will cause brown rust streaking of the sealer.

2. Foundry spent sand. It may contain various metals that may interfere with the stability of the sealer and its performance. Additionally, foundry sand becomes very fine and has excessive absorbance for the sealer. Sealer thus absorbed by the foundry sand may not be sufficient to bond to the pavement and adhesion failure may result.

3. Beach Sand, (unwashed) because of the very high salt content that will make the sealer film water sensitive, which may lead to premature wear and tracking.

4. Any recycled sand which may contain harmful metals and organic compounds.

Use only water washed, clean, angular silica sand or aggregate.

Conclusion

Use washed dry silica sand /aggregate that shall be angular, free of dust, trash, clay, organic matter or other contaminants and meet the gradation requirements per sealcoat manufacturers specifications.

Written by Girish Dubey of Star Seal, Inc. Visit their web site at www.starseal.com